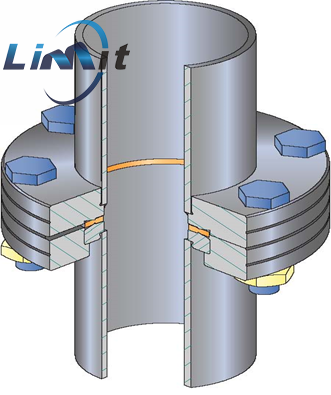

CF 4-WAY CROSSES

Product Description

CF flanges come in two forms: threaded hole flanges and through hole flanges. CF threaded hole flanges can choose from UNC, UNF, or metric threads.

For the convenience of installation, CF flanges are divided into fixed flanges and rotary loop flanges. For installation locations with required installation angles, rotary loop flanges can be selected.

A threaded flange is usually a through hole on one flange, and another matching flange is threaded. Stainless steel bolts are threaded through the through hole flange and locked onto the threaded flange. No nuts required

Through hole flange is fixed to each other by stainless steel bolts and nuts or steel plate nuts. The center of the steel plate nut is in the middle of two adjacent holes, which can replace the outer hexagonal head nut.

Technical Parameter

Specification range: CF16, CF35, CF63, CF100, CF150/160

Flange material: 304 stainless steel or 316L stainless steel

Sealing material: oxygen free copper washer or fluororubber ring

Fasteners: bolts, screws, nuts, spring washers, steel plate nuts

Vacuum range:>1.3E-11pa (oxygen free copper ring),>1.3E-6pa (fluororubber ring)

Temperature range: -200 ℃~450 ℃ (oxygen free copper ring), -20 ℃~200 ℃ (fluororubber ring)

Assembly Method and Steps

Vacuum Easy Buy recommends using high-temperature thread lubricant on all CF flange threaded fasteners (to avoid trouble caused by fastener slippage). It is recommended to use dust-free gloves for assembly when operating and installing CF components. Because even slight fingerprints or other stains can affect the vacuum level.

Carefully inspect the smoothness or roughness of the sealing surfaces of each flange and sealing gasket before installation.

Ensure that the sealing gasket and flange face are parallel, aligning the leakage test slots of the mating flanges, then install the bolts and tighten them

Tighten the bolts in a clockwise or counterclockwise direction, and use an appropriate torque value to tighten each bolt 1/4 to 1/2 turn at a time until the mating flange surface comes into contact with the surface

Quality Assurance

① Strict material selection

Choose Baosteel materials for processing to ensure reliable material quality.

② Integrated flange processing and forming

All components have a bright and smooth surface, with no burrs or burrs on the surface,

R1.5mm perfect rounded corner

Fit dimension tolerance range: ± 20~50 μ M,

Surface roughness range: 0.8~1.6 μ M.

③ Welding component leakage detection

Vacuum welded components will be tested for leakage rate values ≤ 1E-11 pa. m3/s using a helium mass spectrometer leak detector.

④ Product cleaning and surface treatment

Vacuum products have undergone ultrasonic cleaning and electrolytic polishing of welded parts.

⑤ Baking and degassing

All components undergo a baking and degassing process, reducing the time customers need to obtain the desired vacuum degree and ensuring quality.

⑥ The product has interchangeability characteristics

The ultra-high vacuum components adopt both metric and British standards, and can be used in conjunction with domestic and foreign instruments. The products have the characteristic of interchangeability.

⑦ Product vacuum packaging

After vacuum degassing, all vacuum products are vacuum packaged.

Click To Download:DT4-CF16.STEP

Click To Download:DT4-CF35.STEP